ZQA gear reducer: comprehensive analysis of high-precision hardened cylindrical gear reducer

ZQA gear reducer is a hard-tooth surface cylindrical gear reducer improved on the basis of ZQ type reducer. It is specially designed for heavy-duty industrial equipment and is widely used in metallurgy, mining, lifting and transportation and other industries. In order to improve the bearing capacity of the gear and facilitate the replacement of the ZQ reducer, the material of the gear shaft is changed while the shape, shaft end and installation dimensions remain unchanged. The gear shaft is 42CrMo and the large gear is ZG35CrMo. The tempered hardness of the gear shaft is 291~323HB, the large gear is 255~291HB.

Features of ZQA gear reducer

High load-bearing capacity: Using high-quality alloy steel gears and carburizing and quenching hard tooth surface technology, the gears have high strength and excellent wear resistance. Suitable for working environments with heavy loads and shock loads.

High transmission efficiency: Optimized tooth profile design, high gear meshing accuracy, transmission efficiency can reach more than 96%.

Compact structure, flexible installation: modular design, multiple installation forms (horizontal, vertical) optional to meet different equipment needs.

Long service life: The gears are precision machined and heat treated to extend equipment life and reduce maintenance frequency.

Easy maintenance: standardized design, strong interchangeability of parts, and low maintenance cost.

Application of ZQA gear reducer

ZQA type reducer is widely used in the following fields due to its high-strength hard tooth surface and heavy-duty transmission capability:

Metallurgical equipment: rolling mill, continuous casting equipment

Mining machinery: crushers, conveyors

Lifting and transportation: bridge and gantry cranes

Cement building materials: mixer, rotary kiln

Chemical equipment: reactor, stirrer

Model and parameters of ZQA gear reducer

ZQA type reducer is available in a variety of models depending on the center distance and transmission ratio to meet different industrial needs.

| Model | Center distance (mm) | Input power (kW) | Output torque (N·m) |

| ZQA250 | 250 | 4.5~19 | 1100~2000 |

| ZQA350 | 350 | 7~40 | 2500~5000 |

| ZQA400 | 400 | 10~50 | 4000~8000 |

| ZQA500 | 500 | 18~80 | 6000~12000 |

| ZQA650 | 650 | 45~150 | 15000~30000 |

| ZQA750 | 750 | 60~200 | 20000~40000 |

| ZQA850 | 850 | 80~250 | 30000~50000 |

| ZQA1000 | 1000 | 100~300 | 40000~60000 |

| ZQA1250 | 1250 | 150~400 | 50000~80000 |

Difference between ZQA type and ZQ(H) type reducer

ZQA type: hard tooth surface, higher gear precision, suitable for higher load and precision transmission requirements.

ZQ(H) type: hard tooth surface, but the accuracy is slightly lower than ZQA type, suitable for conventional heavy-load transmission occasions.

Selection guide for ZQA gear reducer

When selecting a ZQA gear reducer, please consider the following factors:

1. Load capacity and output torque: Calculate the required output torque and input power based on the workload of the equipment.

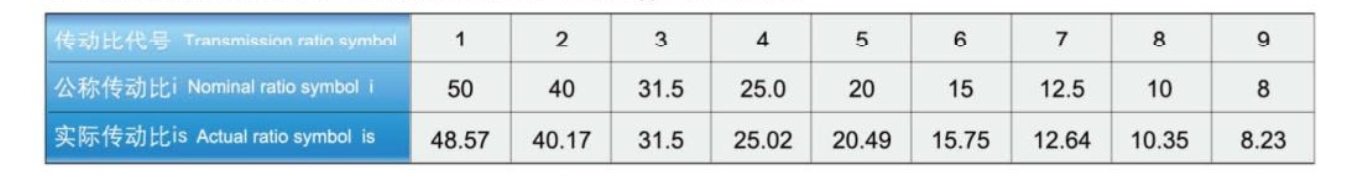

2. Transmission ratio selection: According to the required reduction ratio, ensure that the output speed matches the equipment.

3. Installation method: According to the equipment space and structural requirements, choose horizontal or vertical installation method.

4. Working environment: In special environments, such as high temperature, humidity, and dust environments, a reducer with higher sealing performance should be selected.

Contact us immediately to get more product details and professional selection services of ZQA gear reducer to help you improve equipment performance and ensure stable production operation!Whatsapp: +86 18015057952