Introduction

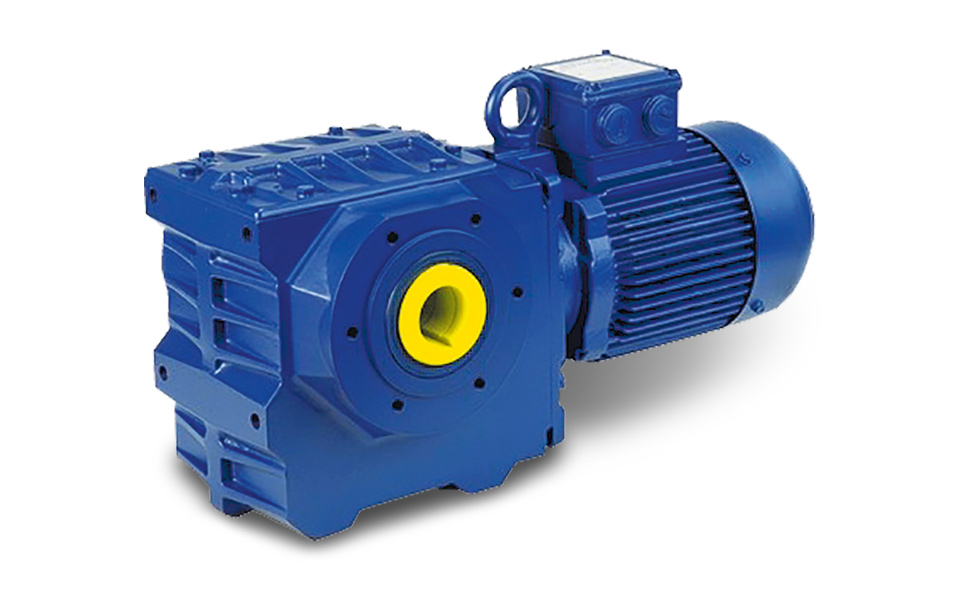

The reducer is an independent component composed of gear transmission, worm transmission, and gear-worm transmission enclosed in a rigid shell. It is often used as a reduction transmission device between the original moving part and the working machine. It plays the role of matching the speed and transmitting torque between the prime mover and the working machine or the actuator. It is widely used in modern machinery.

The reducer is generally used for low-speed and high-torque transmission equipment. The motor, internal combustion engine or other high-speed running power is used to achieve the purpose of deceleration through the gear with a small number of teeth on the input shaft of the reducer and the large gear on the output shaft. The reducer will also have several pairs of gears with the same principle to achieve the ideal deceleration effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

Classification

The reducer plays the role of matching the speed and transmitting torque between the prime mover and the working machine or the actuator. It is a relatively precise machine. The purpose of using it is to reduce the speed and increase the torque. It has a wide variety of different models, and different types have different uses. There are many types of reducers. According to the transmission type, they can be divided into gear reducers, worm reducers, cycloid reducer and planetary gear reducers; according to the number of transmission stages, they can be divided into single-stage and multi-stage reducers; according to the gear shape, they can be divided into cylindrical gear reducers. According to the arrangement of transmission, it can be divided into expansion reducer, split reducer and coaxial reducer.

Feature

The main feature of the worm gear reducer is that it has a reverse self-locking function and can have a larger reduction ratio. The input shaft and the output shaft are not on the same axis or on the same plane. But generally the volume is large, the transmission efficiency is not high, and the accuracy is not high. The harmonic drive of the harmonic reducer uses the controllable elastic deformation of the flexible element to transmit movement and power. The volume is small and the accuracy is high. However, the disadvantage is that the flexible wheel has a limited life and is not resistant to impact. The rigidity is compared with metal parts. difference. The input speed cannot be too high. The advantages of planetary reducer are compact structure, small return clearance, high precision, long service life, and large rated output torque. But the price is slightly more expensive. The gear reducer has the characteristics of small size and large transmission torque. The gear reducer is designed and manufactured on the basis of a modular combination system. There are a lot of motor combinations, installation forms and structural schemes, and the transmission ratio is finely graded to meet different operating conditions and realize electromechanical integration. The gear reducer has high transmission efficiency, low energy consumption and superior performance. Cycloidal pin gear reducer is a transmission model that adopts the principle of cycloidal pin tooth meshing planetary transmission. It is an ideal transmission device with many advantages, a wide range of uses, and can run forwards and backwards.

Function

- Reduce the speed and increase the output torque at the same time. The torque output ratio is the motor output multiplied by the reduction ratio, but it must be noted that the rated torque of the reducer cannot be exceeded;

- Deceleration reduces the inertia of the load at the same time, and the reduction in inertia is the square of the reduction ratio.

Application field

The reducer is a mechanical transmission device in many fields of the national economy. The product categories involved in the industry include various gear reducers, planetary gear reducers and worm reducers, as well as various special transmission devices, such as speed increasing devices and speed regulating devices. Devices, and various composite transmission devices including flexible transmission devices. The product service area involves metallurgy, non-ferrous metals, coal, building materials, shipbuilding, water conservancy, electric power, engineering machinery and petrochemical industries.

The development history of the reducer industry in my country has been nearly 40 years, and the reducer products have been widely used in various fields of the national economy and national defense industry. Food and light industry, electrical machinery, construction machinery, metallurgical machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, transportation machinery, building materials machinery, rubber machinery, petroleum machinery and other industries Reducer products are in strong demand.

The huge potential market has spawned fierce industry competition. In the cruel market competition, enterprises in the reducer industry must accelerate the elimination of outdated production capacity, vigorously develop high-efficiency energy-saving products, make full use of the national energy-saving products benefiting people project policy opportunities, and increase product renewal efforts , Adjust the product structure, pay attention to the national industrial policy, in order to cope with the complex and changeable economic environment, and maintain a good momentum of development.