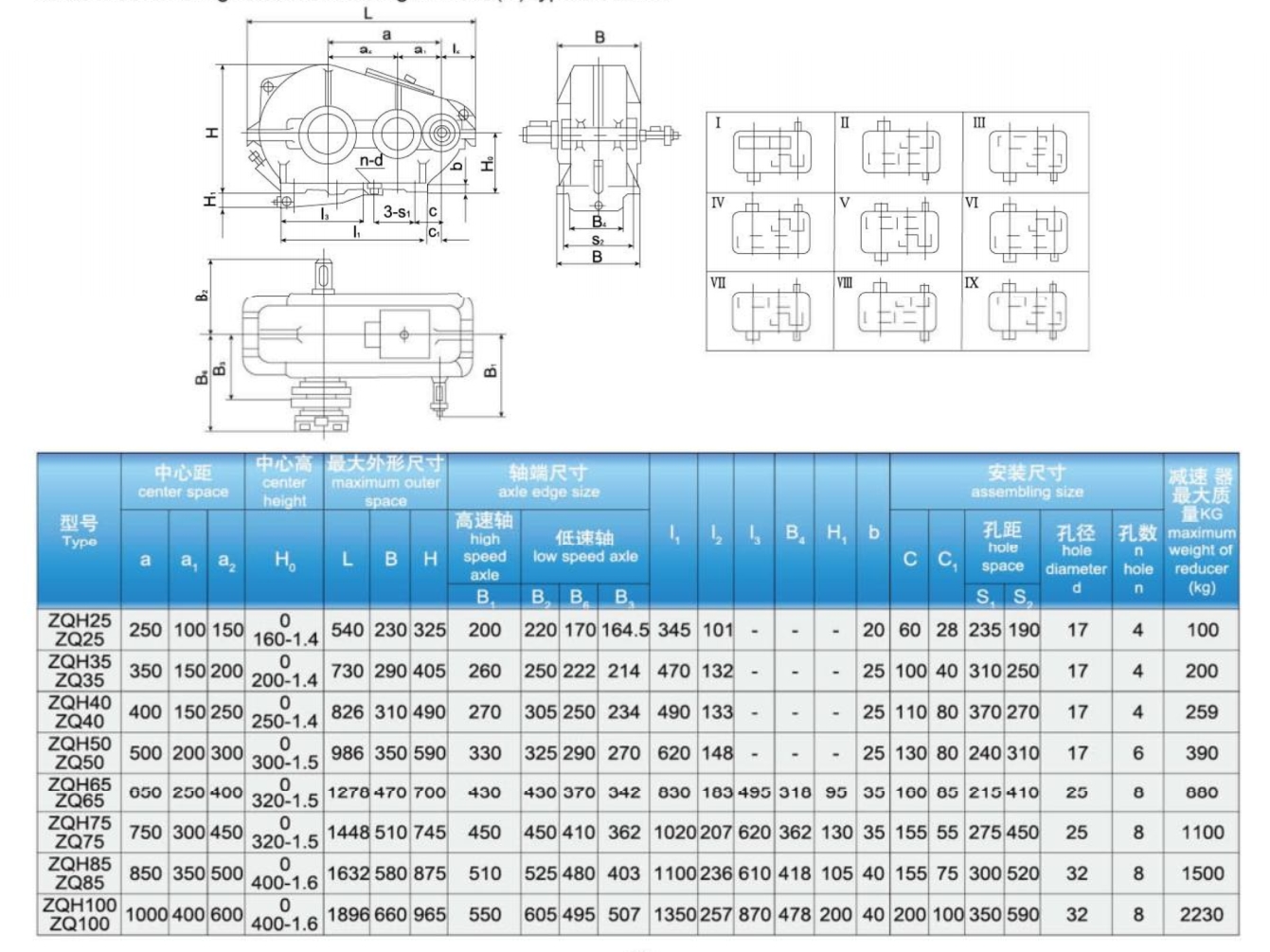

ZQ(H) Cylindrical Gear Reducer Model Analysis and Selection Guide

ZQ(H) series cylindrical gear reducer is a high-performance reduction equipment widely used in industrial fields. It is mainly used in low-speed and high-torque power transmission applications, such as mining machinery, lifting equipment, conveying machinery, etc. The applicable conditions are as follows:

The peripheral speed of the reducer gear transmission is not greater than 4 meters/second

The speed of the high-speed shaft of the reducer is not greater than 1500 rpm

The reducer is used for forward and reverse operation. When equipped with a backstop, refer to the direction facing the output shaft end.

The working environment temperature of the reducer is -40℃ to +40℃

The reducer has nine transmission ratios, nine configuration types and three low-speed shaft end types

Features of ZQ(H) cylindrical gear reducer

High load-bearing capacity: Made of high-quality alloy steel gear material, carburized and quenched. Hard tooth surface design has stronger load-bearing capacity and wear resistance.

Compact structure: modular design, small space occupation, suitable for installation of equipment with limited space.

High transmission efficiency: Precision gear design, transmission efficiency is as high as over 95%, effectively reducing energy consumption.

Low noise and smooth operation: Optimized tooth shape and tooth surface treatment to ensure low noise and smooth transmission.

Easy maintenance: simple structure, strong parts versatility, and convenient maintenance.

Application

ZQ(H) series cylindrical gear reducers are suitable for a variety of industrial environments, especially in the following areas:

Mining machinery: such as conveying equipment, crushers.

Lifting equipment: such as bridge and gantry cranes.

Metallurgical equipment: such as rolling mills and continuous casting equipment.

Conveying system: such as belt conveyor and chain plate conveyor.

Cement and building materials equipment: such as mixers and rotary kiln drives.

Main Models and Parameters

| Model | Center distance (mm) | Ratio | Rated input power (kW) | Rated output torque (N·m) |

|---|---|---|---|---|

| ZQ250 | 250 | 8~40 | 4.5~19 | 1100~2000 |

| ZQ350 | 350 | 8~40 | 7~40 | 2500~5000 |

| ZQ500 | 500 | 8~40 | 18~80 | 6000~12000 |

| ZQ650 | 650 | 8~40 | 45~150 | 15000~30000 |

How to choose the ZQ(H) series cylindrical gear reducer?

1. Clarify working conditions

Calculate required output torque and power.

Clarify the usage environment (such as temperature, humidity, dust).

2. Choose the appropriate transmission ratio

Select the appropriate transmission ratio according to the output speed requirements of the equipment.

3. Consider equipment size and installation method

Select the appropriate center distance and structural form of the reducer according to the space constraints of the equipment.

4. Load type

Determine whether it is a constant load or an impact load to select a higher strength hard tooth surface reducer.

Contact us now to get more product details and professional selection guidance of ZQ(H) series cylindrical gear reducers to help you optimize equipment performance and improve production efficiency! Whatsapp: +86 18015057952